Platform Overview

Monitor, Control & Optimize Your Environment.

In this platform overview, learn how Prophecy IoT®’s suite of services transforms your shop floor into a living network, where machines and people communicate seamlessly. Machines become connected intelligent entities and workers are empowered with simple interactions, adapting and optimizing their performance in real-time.

Isolate Your Productivity Killers

- Modern

- Smart

- Simple

- Leading-Edge

Goodbye, Tedious Hello, Streamlined.

Prophecy IoT® is a platform designed to boost productivity, streamline processes, and empower your team for success. Unlike traditional systems and MES solutions that rely on manual input for transactions, Prophecy IoT® modernizes your operation, making time consuming, traditional / transactional input a thing of the past.

Watch the Platform Overview...

Meet Prophecy IIoT’s Suite of Services:

Connected Machines

- Data Collection

- Sensor Technologies

- Machine Health

- Maintenance

Connected Operators

- Production Interfaces

- Quality Control

- Work Instructions

- Real-Time Communication

Connected Supervisor

- Supervisor Dashboards

- In-Process Job Screens

- Scrap & Production Overviews

Connected ERP

- Integrate with ERP

- Planning & Scheduling

- Inventory Management

- Automate Processes

Connected Plant

- Drive Business Outcomes

- Smart Factory

- Executive KPI Metrics

- Process Visibility

Connected Applications

- AI / ML Applications

- Prophecy Database

- Data Analytics

- API

Connected Machines

Data on machine performance, health and production rates, are transmitted in real-time, providing instant visibility into operations.

Connected Operators

Can monitor machine performance, report labor time, complete production runs, and interact with the quality management system.

Connected Supervisor

Shopfloor data and metrics are collected and presented to supervisors in pre-built dashboards to better understand job performance.

Connected ERP

Deep integration with ERP system enables shopfloor process automation around planning and scheduling and inventory management.

Connected Plant

Data analysis leads to valuable insights, optimization opportunities, and informed decision-making across the factory and enterprises.

Connected Applications

An open API environment connects Prophecy to more advanced applications, like AI/ML and data analytics.

How Is The Prophecy IoT® Platform Delivered?

1

Environment Assessment

First, we examine your ecosystem. We conduct a comprehensive assessment of your factory, assets, machinery, processes, and existing data collecting systems. Then, we develop a game plan to seamlessly connect all data points into Prophecy IoT® for real-time visibility into your operations.

2

The Game Plan

The goal is to streamline communication and collaboration by ensuring every key aspect of your factory collects usable data. Your machines are already produce this valuable data every second, and by collecting and utilizing this data combined with manufacturing job and quality information, we can enhance your processes significantly. We are after the data.

3

Installation

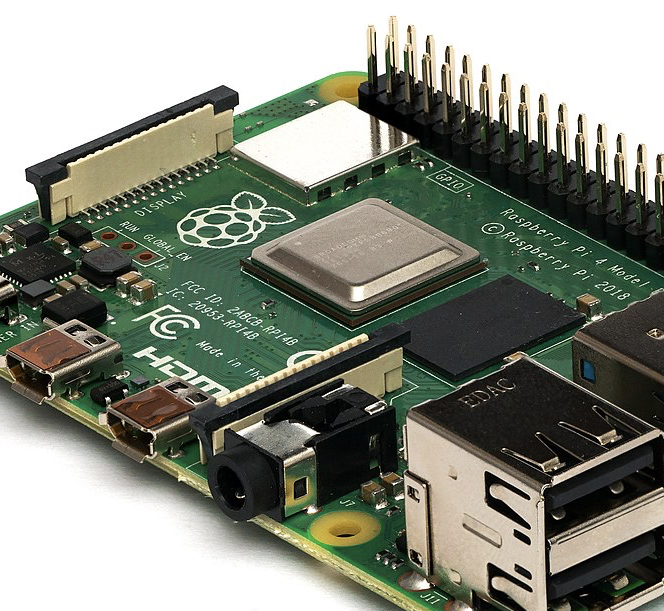

Using simple, inexpensive devices and sensors like RFID/Barcode, scales, cameras, IoT sensors, stack lights, temp and humidity devices, and others, Prophecy captures accurate data from key points in your specific manufacturing process. You don’t need the latest and greatest machines to make the most of your living network.

4

Using Your Data

Once the data is collected from key points in the manufacturing process, Prophecy IoT® performs a range of crucial functions that drive efficiency:

Displaying Data

Prophecy IoT® presents your information in a user-friendly dashboards and LIVE Andon boards, offering a comprehensive overview of your factory’s live performance. This scoreboard view can be easily customized to your specific needs, allowing you to drill down into each section for a more detailed and granular analysis.

Alarms & Boundaries

Prophecy IoT® enables the setup of alarms and boundaries to ensure proactive monitoring to stop unplanned downtime. Instantly receive notifications when operators detect a problem, or when machines output a fault code indicating a problem. These alarms can also be configured to detect RATE of CHANGE on any type of machine variable like temperature, pressure, load, RPM, etc.

Forecasting Your Environment

Prophecy IoT® provides real-time data monitoring and creates a living network within your factory. Most MES systems rely SOLEY on transactions to be MANUALLY entered into to a system, posted, and then reviewed later to determine if a problem exists. This is both time-consuming and very inefficient. Prophecy is a living network that does not operate based solely on transactions. Prophecy operates in the present while providing essential data for informed decision making. By leveraging this forecasting power, you can save valuable time, optimize resource allocation, and reduce costs within your environment.

The Result:

A Revolutionized Manufacturing Process

The level of clarity that Prophecy IoT® provides in your existing environment opens the door to unparalleled levels of efficiency, sustainability, and productivity for your enterprise.

Data-driven analytics propel smart and simplified decision making that help you monitor, control, and optimize your shopfloor.

No Machine? No Problem.

Prophecy IoT® offers flexible solutions that seamlessly work with your existing equipment and manual processes.

By utilizing simple and cost-effective devices, sensors, and displays, you can capture the critical data we’ve been talking about and create your living network without extensive upgrades.

No matter the manufacturing operation, Prophecy can connect and provide valuable insights into your workflow.

Valuable 24/7 Insights

Without Operator Input

With Prophecy IoT®, we seamlessly capture data from your entire shop ecosystem around the clock. Through advanced monitoring, we unveil a wealth of insights into your operations: identifying patterns, detecting anomalies, and generating valuable insights.

Tap into the power of this information, unlocking a new level of understanding that empowers you to make informed, smart decisions that optimize your manufacturing processes.

The Design Studio

Since all manufacturing companies and processes are unique, we created the design studio to support many manufacturing Use Cases. The design studio is a software tool or environment designers and engineers use to create graphical user interfaces for Andon boards and human-machine interfaces (HMI). HMIs are crucial in industrial settings, allowing operators and users to interact with and monitor complex machinery, control systems, and processes. The design studio provides a platform for creating visually intuitive, user-friendly, and efficient interfaces.

The design studio facilitates the integration of the HMI with underlying control systems, sensors, and databases Allowing designers to configure data sources, establish communication protocols, and ensure seamless connectivity.

Customize Andon Boards

NO CODE: Drag-And-Drop Interface

Integrate Underlying Control Systems, Sensors, and Databases

Configure Data Sources And Protocols

Cyber Security:

Safe Data, Safe Access

Security is a top priority at Prophecy IoT®. Our platform has been developed with robust measures to protect your data, devices, and infrastructure.

From advanced threat detection to encryption and access controls, Prophecy IoT® ensures your information is safeguarded against potential risks.

Unlock the Power of Prophecy IoT®

Recognizing the connections between the environment, machines, and individuals, Prophecy IoT® is here to enhance your manufacturing capabilities, optimize communication, and transform your business.